The air compressor central controller is an important part of the air compressor system, helping to control and manage the operation of the air compressor to ensure the highest working efficiency while saving the most energy.

Feature

-

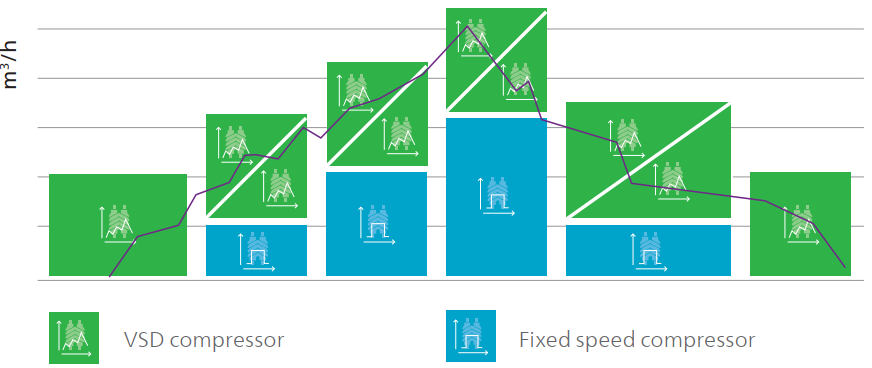

- Control run/stop, adjust inverter speed, load/unload fixed speed machines based on pipeline pressure as well as priority and running hours of each machine

- Monitor machine running/stop/load/unload/shutdown/warning status

- Central controller on/off operation and switching between two operating pressure band can be selected manually from the control display; by toggle switch; by industrial communication network; or by the timer in the control display

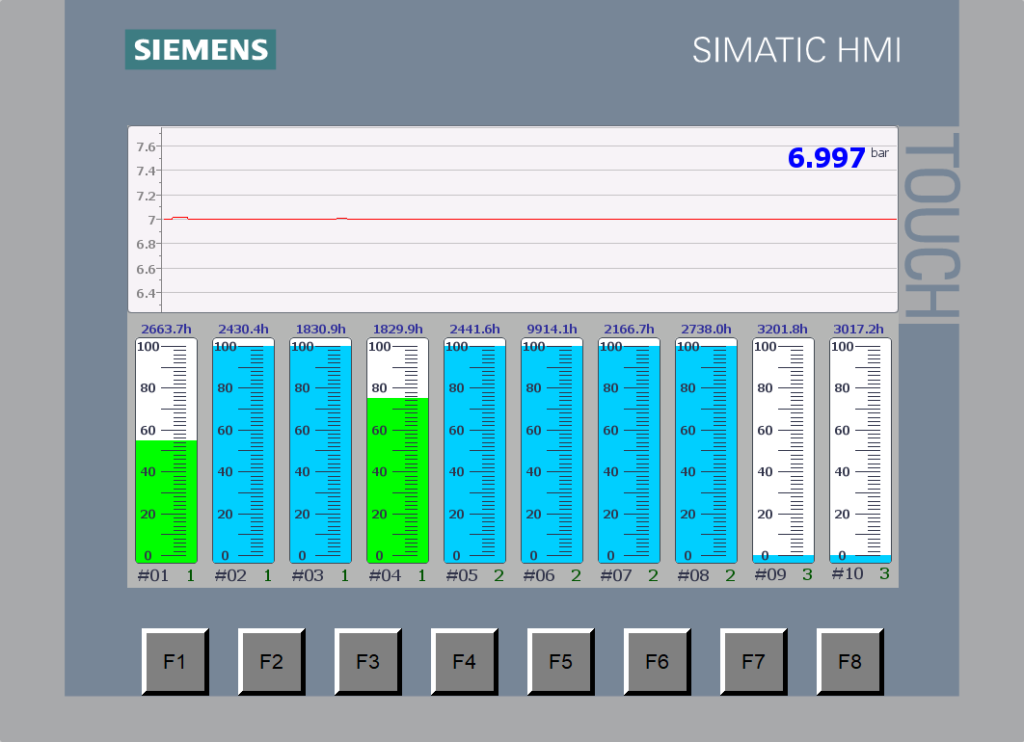

- Control 6 / 10 / 16 machines depending on controller type. Connect via industrial communication network, hard wire… air compressors, air dryers of many different brands Atlas Copco, Ingersoll Rand, Kobelco, King Power, …

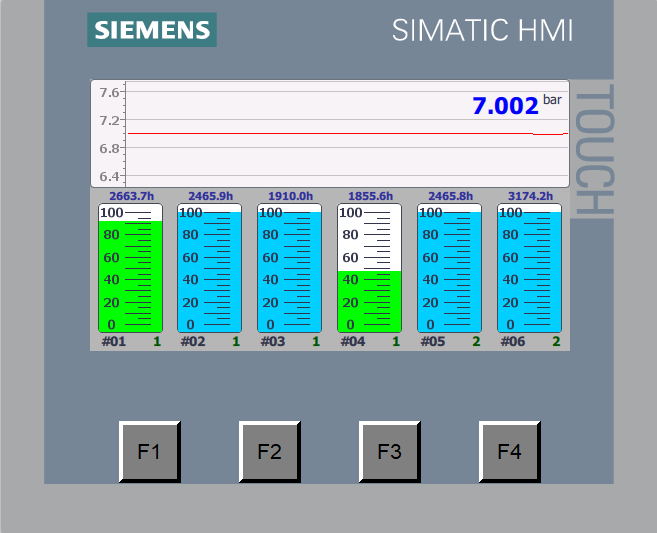

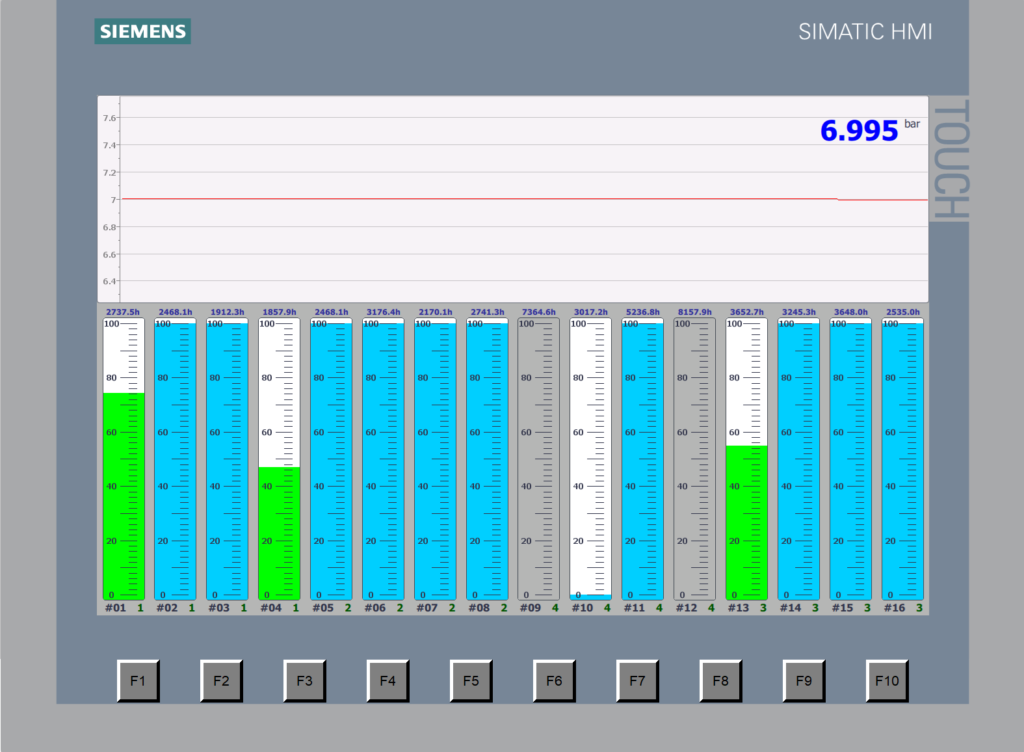

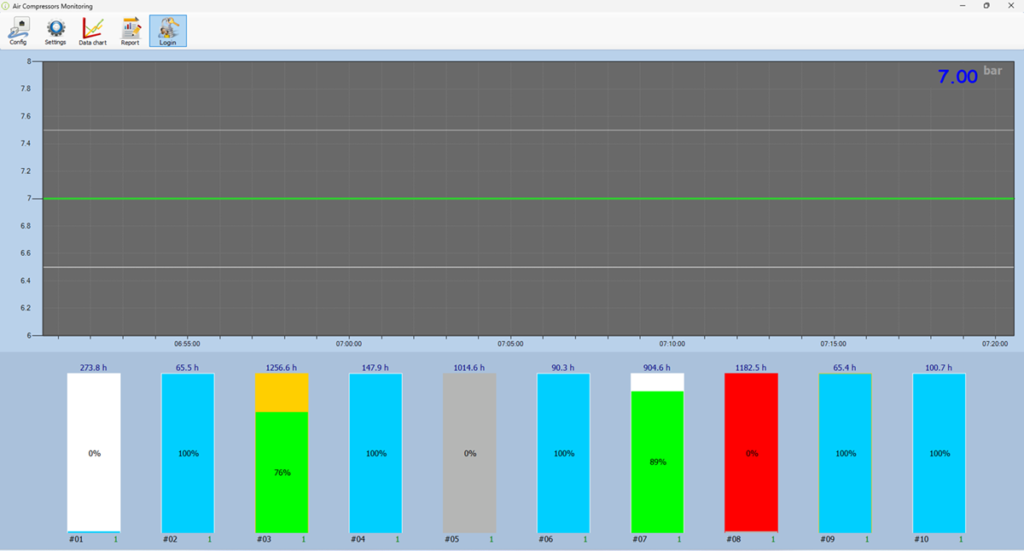

- Parameters are monitored on a 4″ / 7″ / 12″ touch screen corresponding to the controller of 6 / 10 / 16 machines

- Three dry contacts are available for high / low / ok pipeline pressure with threshold values set from the screen

- Connect directly to the monitoring software (free) on your computer to monitor and store data via LAN network

- The central controller is built from a Siemens (Germany) PLC programming controller, which operates extremely stably and durable, with the ability to expand and connect flexibly with the SCADA factory monitoring system. , DCS: (available) profinet, modbus tcp/ip ; (optional) ethernet-ip, profibus, modbus-rtu,…

- Option to connect a dewpoint sensor, as well as set dewpoint warning values

- Optional connection to air compressor system power consumption meter

Benefit

-

- Equalization of running hours: allows maintenance of multiple machines at the same time, increasing machine stability and working time

- Reduced idling time: the machine is managed to run/stop based on the plant’s compressed air demand. Helps minimize wasted idling time, thereby saving energy consumption

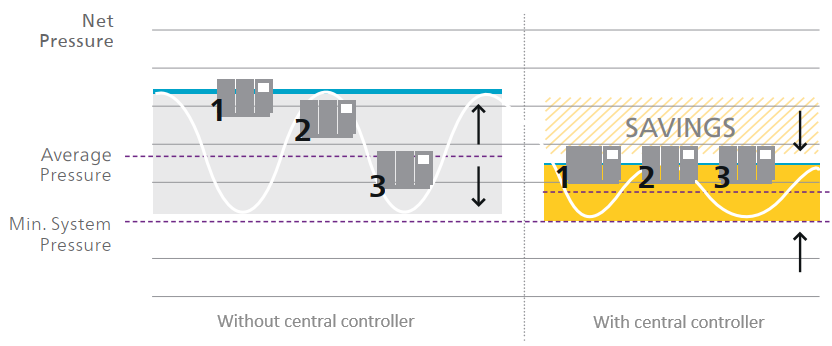

- Reduced pressure band: Without a central controller, air compressors have to work with a large load/unload pressure band. Run/stop/load/unload operations are decided by the machine’s controller. There is no connection rule between machines, which increases idling time, machines run more time, machines run less time, and pipeline pressure fluctuates widely. The central controller will keep pipeline pressure within a smaller band, which increases the stability of the production line as well as optimizes overall energy consumption. The controller only maintains the optimal number of compressors running according to the plant’s compressed air demand..

- Automatic stop and restart: Turning off the compressed air system during non-production can reduce more than 20% of the energy normally lost due to air leaks

Central air compressor controller with one inverter and five fixed speed machines

If you need any further information, please do not hesitate to contact us

Hotline: (+84) 9O3 O7 11 OO Email: sales@cdtnova.com.vn

Đánh giá

Chưa có đánh giá nào.